KO-YAN machinery leads customers to implement low-carbon manufacturing with industrial recycling services

KO-YAN Precision Machinery (COMORK) is located in the precision machinery cluster in central Taiwan, which has the highest output value per unit area and the highest density in the world. It stands out among tens of thousands of upstream and downstream supply chains. There is no other reason. KO-YAN machinery, which started from precision machining, puts users' experience into equipment research and development, as a whole , which is undoubtedly a great boon to the industry.

At the beginning of 2024, consultants from the Plastics Industry Technology Development Center (Plastics Center) visited the factory to diagnose and promote circular economy concepts. They also better understood how to achieve various life cycles from equipment design, manufacturing, use to recycling. stage, becoming the key player in leading customers to implement circular economy.

Because of KO-YAN Machinery's solid metal processing technology and machinery research and development experience, under this wave of circular economy, it is fully able to serve customers with the thinking of "industrial cycle", including:

- Product design: The modularization of mechanical components makes the equipment easy to disassemble, repair, upgrade, remanufacture and recycle, extending the durability of the equipment, not only saving energy but also reducing resource consumption.

- Process optimization: The innovative design of the "Internal and External Diameter Compound Grinding Machine" integrates the functions of the internal and external diameter grinders, which not only ensures product accuracy and yield requirements, but also allows users to perform a single clamping operation at a time. The machine performs multi-surface grinding, which greatly improves production efficiency and space utilization, maximizing resource utilization efficiency.

- Refurbishment/remanufacturing : Through complete inspection and parts replacement, the equipment is restored to a nearly new state, specifically extending the service life of the equipment and reducing the generation of scrap metal such as casings, achieving carbon reduction benefits.

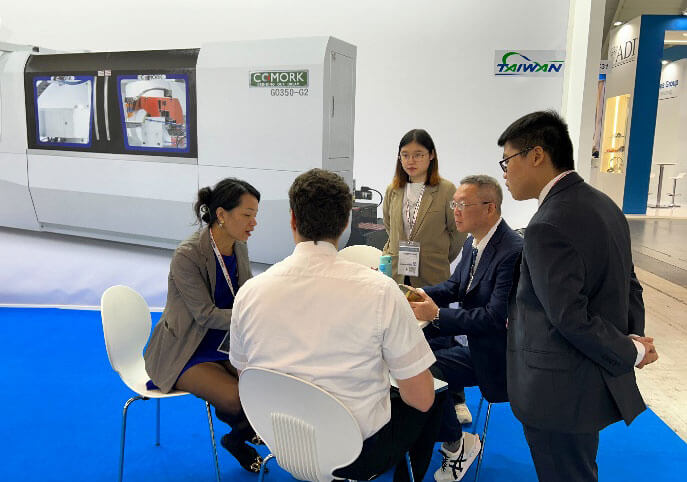

KO-YAN Precision Machinery sells OEM/ODM grinding machines and grinding machines internationally. Immediately after the epidemic, many international exhibitions were arranged, including going to Stuttgart, Germany for the first time this year to participate in GrindingHub 2024 hosted by the German Machine Tool Manufacturers Association (VDW). The company received positive feedback from many European buyers at the exhibition. General Manager Zhou Quanji said that the COMORK brand has great potential in Europe and has actively handled inquiry orders from Germany, Turkey and other Eurasian markets, which can be said to be a great success.